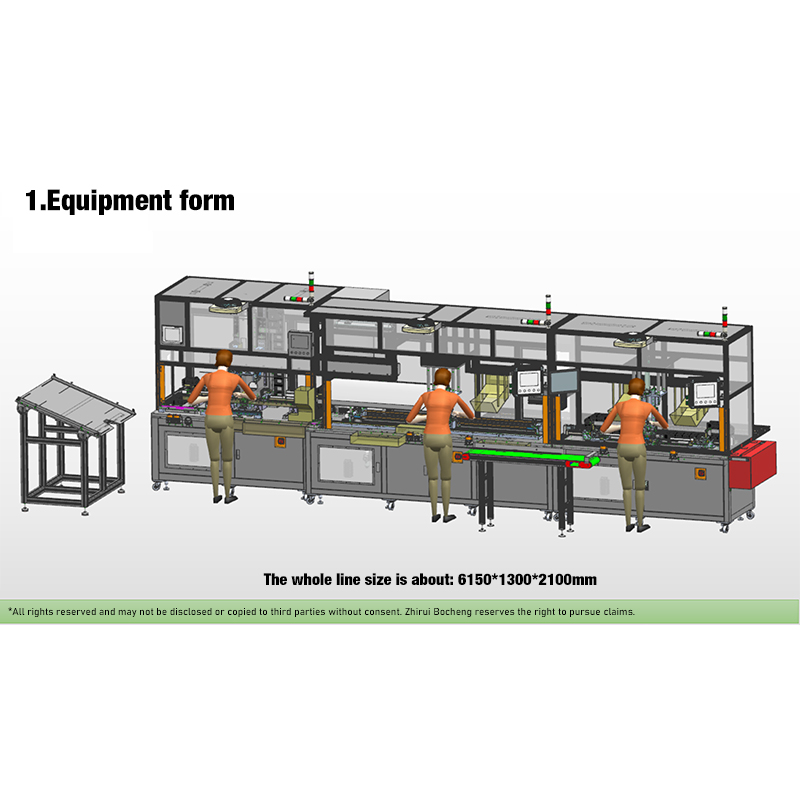

Welding four-wire equipment solution

1. The production line is divided into three stations, namely, springs, bracket pre-assembly, welding, brushes, guide plates, accessory assembly, buckle assembly, and laser marking. 2. The equipment is compatible with boneless products with lengths ranging from 350mm (14 inches) to 800mm (32 inches). For different series of products, the production can be switched by replacing the jig. Products of the same series with different lengths do not need to replace the jig, but only need to adjust the servo motor position parameters. 3. The parts currently considered for production on this line are: 1) 2 types of brackets, bulk. 2) 6 types of accessories, bulk. 3) 2 types of buckles (divided into A and B buckles), bulk material frames. 4) 1 type of guide plate, different lengths, bulk. 5) 2 types of brush plates, length 350-800mm. 6) 1 type of spring thickness (spring thickness 1.03), length 350-800mm

4.350mm (14 inches, inclusive) ~ 800mm (32 inches, inclusive) whole line beat ≤ 12S (including equipment and personnel operation time).

5. Equipment operation mode: semi-automatic and manual mode

1) Each station can be used separately.2) All motion actuators can be manually controlled separately.

3) The action of a cycle can be controlled separately.4) When there are defective products that need to be reworked, the manual mode can be selected.

6. The first station of the bottom frame adopts 80*80*4mm square tube welding. The second and third stations adopt 60*60*4 square tube welding. The aluminum profile used is 45*45 aluminum profile with a wall thickness of 2mm. The acrylic plate used is colorless frosted translucent acrylic with a thickness of 4mm.

Equipment efficiency CT: 12S/pcs

Power supply voltage: Single phase: 220V, 50 Hz, 10%.

Three phase: 380V, 50 Hz, 10%. Compressed air: 5±1bar

Working environment Temperature: +5℃~+40℃

Noise: Max: ≤75dBa