Copyright © Jiangsu Zhirui Bocheng Energy Technology Co., Ltd. All Rights Reserved. Site Map

- +86-15295075906

- suyanqin@zckj-js.com

- No. 17, Beitanghe East Road, Tianning District, Changzhou City

- Home

-

Products

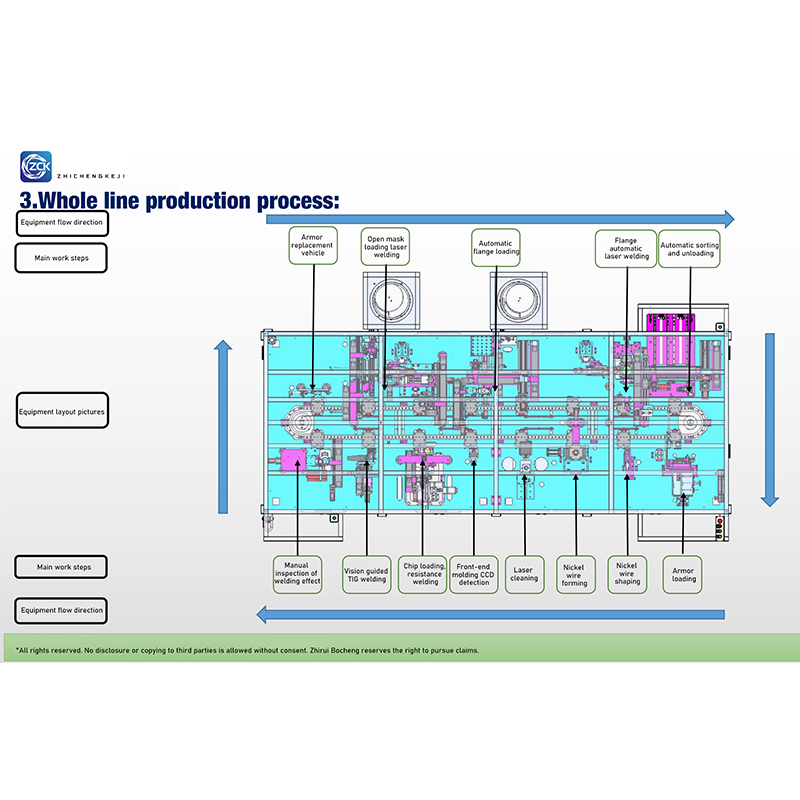

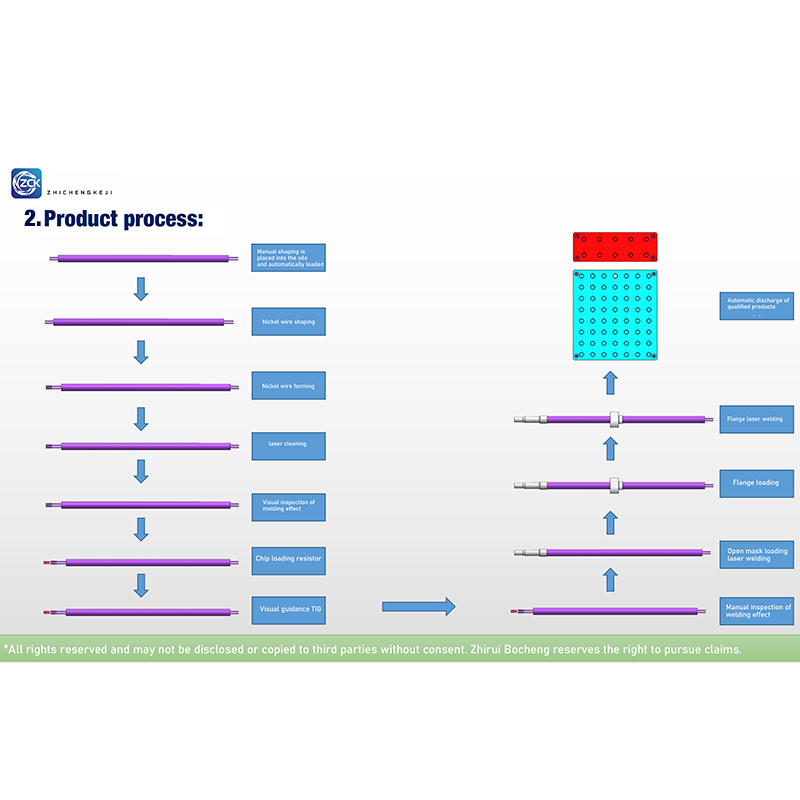

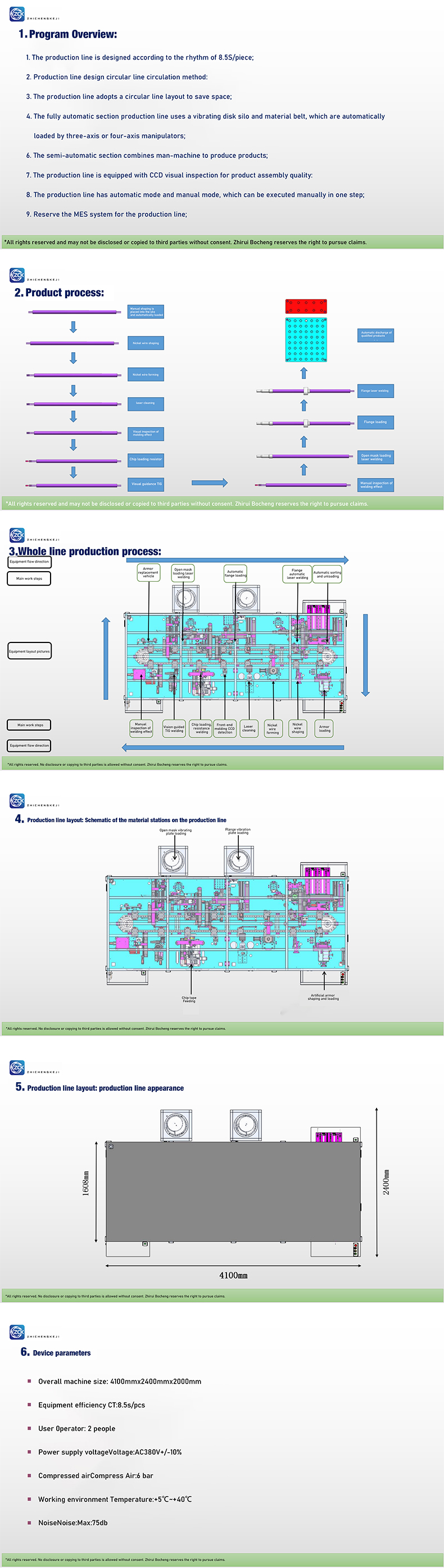

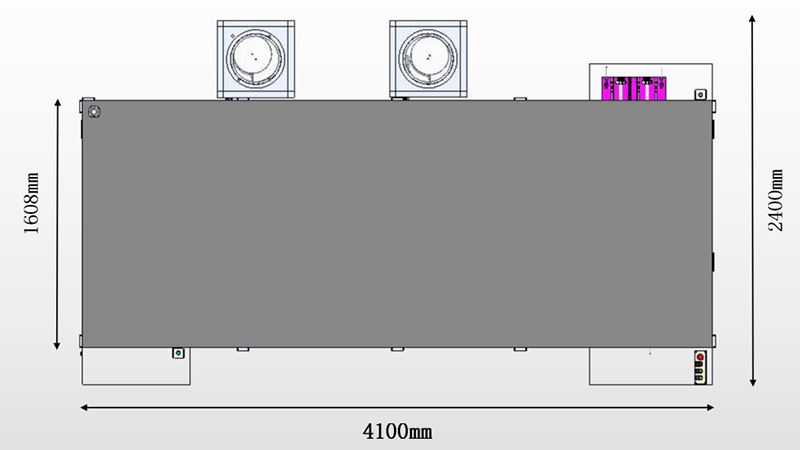

- PT200 Chip & Cap & Flange Automatic Welding Line Solution

- Introduction To Axle Project

- Hydrogen Energy Battery Solution

- Thermal Management System Solution

- Wiper Solution

- Welding four-wire equipment solution

- Post-scraping welding line equipment solution

- Inkjet Printing Detection Equipment Solution

- Wiper frame assembly line solution

- Wiper parts assembly and angle detection solution

- Air heating plan

- Display

- Solutions

- News

- About

- Contact Us

- Partners